AI Powered Manufacturing Innovation Research

Artificial intelligence (AI) is spreading globally as rapidly as the internet technologies we are so familiar with. While simple, repetitive physical tasks have already been replaced by automation through robotics, artificial intelligence now demonstrates the potential to handle far more complex and sophisticated tasks that were previously considered the domain of skilled human expertise. In fact, AI is even solving problems that are so intricate they were beyond human capability. In the manufacturing industry, a cornerstone of our nation’s economy, AI goes beyond merely addressing inefficiencies caused by human labor. It contributes to maximizing productivity and quality at levels previously unattainable with existing technologies, while also addressing environmental issues. Our research goal is to enhance productivity, product quality, and safety through AI. By analyzing data generated from machinery on manufacturing sites, we are developing solutions in collaboration with academia and industry to boost actual productivity. Furthermore, we are researching AI-based technologies aimed at achieving ultimate autonomous manufacturing, enabling high productivity and quality with minimal human intervention.

AI-operated robotic systems are studied for autonomous manufacturing systems. AI-based control methods, such as reinforcement and imitation learning, enable unstructured behavior, allowing robots to independently perceive, evaluate, and act in their environment without human intervention. Complex job tasking in factory can be improved with AI-operated robotic system. Human labor trains AI robots to perform specific tasks, allowing human expertise to enhance the robot’s movements for complex jobs that were previously only possible for humans.

AI Powered Materials Research

AI is actively being used in material development as well. In the manufacturing industry, various optimization and search techniques are employed to produce materials that meet customer requirements. Traditionally, experimental approaches and finite element analysis (FEA) methods have been used. However, using experimental approaches to develop materials with desired properties requires significant time and cost. While FEA can predict trends in material properties based on process conditions or material compositions, it does not provide precise process conditions or compositions to achieve the target material properties. AI, on the other hand, can leverage big data related to materials to rapidly identify the desired properties. One of the most effective methods is for AI to learn from sensor data generated by production equipment, which influences material properties, in order to secure the target properties. Additionally, AI trained on past experimental data can digitalize the expertise hidden in the data, enabling workers with no prior knowledge in the field to easily secure optimal material properties. Furthermore, in cases where experimental data is insufficient and additional experiments are needed, AI can assist in quickly identifying target material properties using techniques such as data augmentation, transfer learning, and active learning.

Smart Additive Manufacturing Research

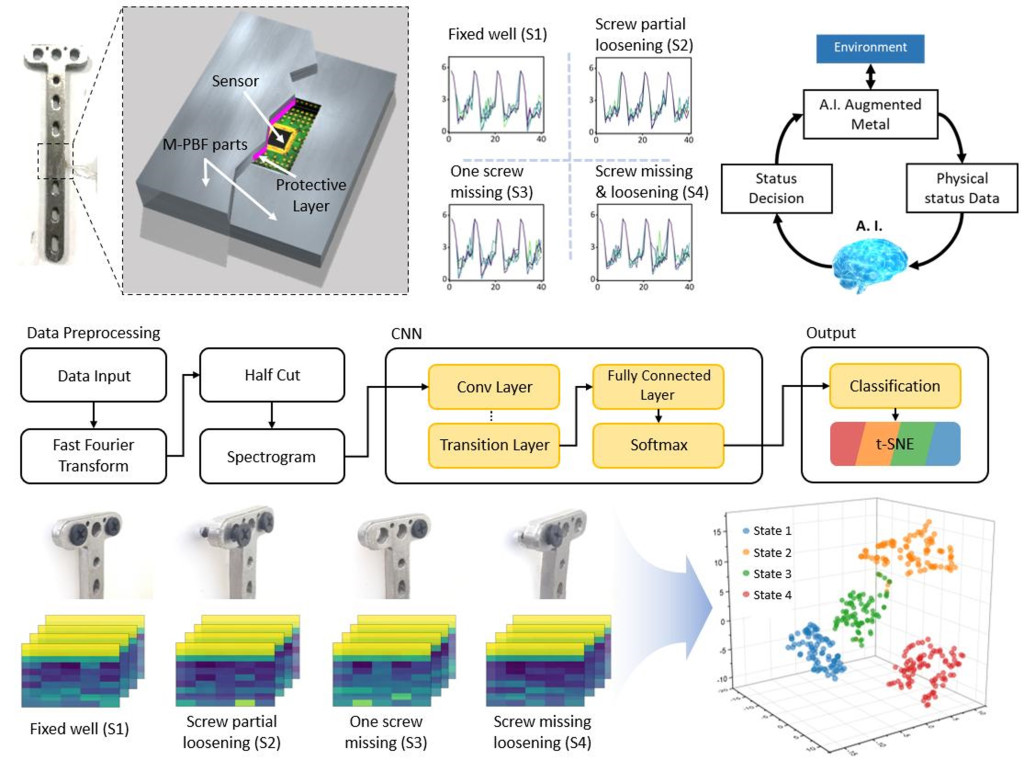

Additive manufacturing is a groundbreaking digital manufacturing technology that enables the creation of three-dimensional shapes in a single step, simply by inputting a digital 3D design. Unlike traditional subtractive manufacturing processes, which involve cutting away material, additive manufacturing builds up material layer by layer. In particular, for functional materials, traditional manufacturing processes often face significant limitations in creating complex 3D shapes. Additive manufacturing overcomes these challenges, enabling the production of components with various complex geometries and sizes tailored to diverse applications. This opens up possibilities for entirely new types of devices that were previously difficult or impossible to realize. For instance, additive manufacturing can facilitate micro-scale printing of electrochromic materials for augmented reality smart contact lenses, production of smart components capable of real-time internal stress monitoring through sensor- and semiconductor-embedded 3D printing processes, and 3D fabrication of perovskite materials that interact with light. Moreover, as a digital manufacturing process, additive manufacturing can be seamlessly integrated with artificial intelligence to achieve unprecedented speeds and precision in 3D shape production. This represents a transformative advancement in the capabilities and applications of manufacturing technology.

3D Printed AR Smart Contact Lens

AI Driven Superfast 3D Printing (< 1minute)

Data Encryption in 3D Structure